Ferro silicon is a ferroalloy composed of ferro and silicon. Ferro silicon is a ferro-silicon alloy made of coke, steel chips, as raw materials and smelted from an electric furnace. Because silicon and oxygen are easily synthesized into silica, ferrosilicon is often used as a deoxidizer in steelmaking, and because SiO2 is generated when a lot of heat is released, it is also beneficial to increase the temperature of molten steel while deoxidizing. Ferrosilicon can also be used as an alloying element additive, widely used in low-alloy structural steel, spring steel, bearing steel, heat-resistant steel and electrical silicon steel, ferro silicon in the production of ferro alloys and chemical industry, commonly used as a reducing agent.

Ferro Silicon Specification

|

Grade |

Si |

Al |

C |

S |

P |

|

FeSi72 |

72%min |

2.0%max |

0.2%max |

0.02%max |

0.04%max |

|

FeSi75 |

75%min |

2.0%max |

0.2%max |

0.02%max |

0.04%max |

|

FeSi75 Low Al |

75%min |

1.0%max

0.5%max

0.1%max |

0.1%max |

0.02%max |

0.04%max |

Ferro Silicon Production Processing

The process of Ferrosilicon production involves the reduction of sand or silica (Si) with coke / coal (C), and then reacting it with iron (Fe) which can be obtained from scraps. The Carbon in the coal is required to remove the oxygen, leaving a pure Silicon and Iron product.

A submerged electric arc furnace can also be used in the production of Ferrosilicon. Quartz is melted together with steel scrap and a reductant. A hot liquid alloy is formed and collect in a sand bed. Once cooled the product is broken into smaller pieces, which will then further be crushed to the desired size.

Ferro Silicon Density

The density of Ferrosilicon is different for different ratios of alloy compositions. FeSi 45 has a density of 5.1 g/cm3. The density of FeSi 75 is 2.8 g/cm3 and FeSi 90 has a density of 2.4 g/cm3.

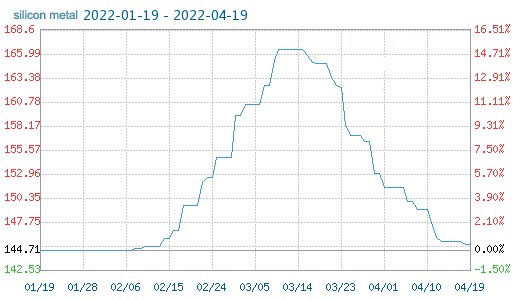

Ferro Silicon Price

Ferrosilicon prices with the market fluctuations continue to adjust, jojoalloy can ensure the quality of the premise, the most suitable price, our goal is to let every customer to be able to work with jojo for a long time.

-

What is ferro silicon used for?

Ferrosilicon (FeSi) is an alloy of iron and silicon with a very variable silicon content between 10% and 90%. It is used as a so-called master alloy in steel production, which is added in small amounts in order to adjust the properties of the melt, the cooling process and the finished product.

-

How do you make ferro silicon?

Fe-Si is produced industrially by carbo-thermic reduction of silicon dioxide (SiO2) with carbon (C) in the presence of iron ore, scrap iron, mill scale, or other source of iron. The smelting of Fe-Si is a continuous process carried out in the electric submerged arc furnace (SAF) with the self-baking electrodes.

-

Where does ferro silicon come from?

Ferrosilicon is produced by reduction of silica or sand with coke in the presence of iron. Typical sources of iron are scrap iron or millscale. Ferrosilicons with silicon content up to about 15% are made in blast furnaces lined with acid fire bricks.

-

Where is ferrosilicon used?

Its applications include deoxidizing steel and other ferrous alloys, making it a so-called master alloy in steel production. In terms of end-use, ferrosilicon is mainly used for the production of carbon & other alloy steels, stainless steel, cast iron, and electric steel.

-

What is the meaning of ferro alloys?

The word ferroalloy refers to an alloy of iron containing a significant proportion of one or more other elements like silicon, manganese, chromium, aluminum, or titanium.

-

What is raw material of ferro silicon?

Main raw materials for Ferro Silicon production are quartz, charcoal and mill scale. Quartz contains chemical gangue besides the conglomerates of surface sticking mud coat and earth materi- als which contributes for slag forming tendencies.